Composite strips

Overview:

Composite strips are rolled with raw materials of different features (composite strips and basic strips) using advanced composite technique according to different use requirements. They can not only keep and fully play the features of composite components, but also generate useful comprehensive performance thanks to composite effect, in particular, the electrical property and wear-resisting property will be improved significantly compared with the entire pure (gold and silver) contact materials, besides, the products can also save precious metals (gold and silver) and reduce product cost. The main product feature are as follows:

① They grant flexibility to material property design to manufacture contact materials optimizing and combing mechanical property and electrical contact property;

② The precious metals (gold and silver) are only composited at necessary position of electrical contact, thus effectively saving precious metals (gold and silver). The price of contact is low;

③ Composite contact materials are suitable for continuous automatic production of contact parts forming, and no other processing technology is needed after forming (such as welding and riveting), in this way, it will not only simplify the manufacturing process of contact parts, improve production efficiency and reduce cost, but also enhance the assembly precision and reliability of components.

Application:

Composite materials are mainly used for production of various micro motor brushes and commutators, microswitches, relays, connectors, tuners and other electronic components.

1. 1.Combination table of previous metal layer and base layer materials

|

Base material/previous metal composite layer |

silver and silver alloy |

gold and gold alloy |

palladium and palladium alloy |

|||||

| Base material | Ag | AgCu | AgNi | AgMeO | AuAg/AgCu | AuAgCu/AgCu | Ag Pd | |

| Copper | C1020 | |||||||

| Tin-phosphor bronze | C5210 | |||||||

| C5191 | ||||||||

| Beryllium Bronze | C1720 | |||||||

|

Packfong |

C7521 | |||||||

| C7701 | ||||||||

| Brass | C2600 | |||||||

| C2680 | ||||||||

| C2801 | ||||||||

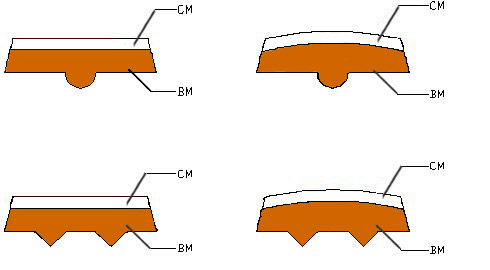

2. Composite shape of precious metal materials

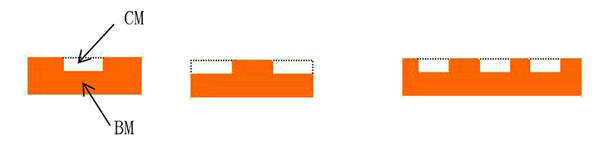

① Single-side strip composite

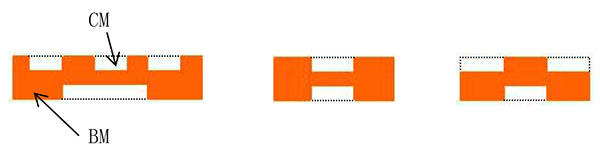

②Double-side strip composite

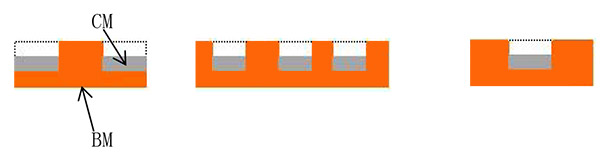

③Three-layer strip composite

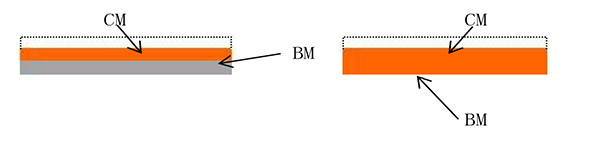

④ Surface composite

⑤Profiled composite

3. Product dimension and tolerance

Thickness range of composite material products: 0.03~1.80 mm; width range: 5~150 mm

|

Product thickness (mm) |

Thickness tolerance (mm) | Width tolerance (mm) | |||||

| standard | high precision | standard | high precision | ||||

| ≥0.03~0.10 | ±0.004 | ±0.003 | ±0.08 | ±0.05 | |||

| ≥0.10~0.25 | ±0.005 | ±0.004 | |||||

| ≥0.25~0.50 | ±0.008 | ±0.005 | |||||

| ≥0.50~0.80 | ±0.015 | ±0.006 | ±0.10 | ±0.08 | |||

| ≥0.80~1.20 | ±0.030 | ±0.007 | |||||

| ≥1.50~2.00 | ±0.045 | ±0.008 | ±0.20 | ±0.12 | |||

|

Width of precious metal composite layer |

more than 1.5mm |

||||||

|

Thickness of previous metal composite layer |

less than 40% of the entire material thickness |

||||||

Inquiry

Contact information

More products

Contact: Ken Chen

Mobile/what’sapp: +86-13929229799

Wechat: Ken_chen3366 Skeype:ken65366

E-mail: sales1@gddjsc.com / sales2@gddjsc.com

Tel: +86-769-82859260

Fax: +86-769-82859261

Address: Room 202, Building 19, Changping Jewelry Culture Industrial Park, Huanchang North Road, Changping Town, Dongguan City, Guangdong Province

Official account

COPYRIGHT © 2021 Dongguan Dianjie Alloy Technology Co., Ltd. All rights reserved 粤ICP备2021072731号Powered by www.300.cn